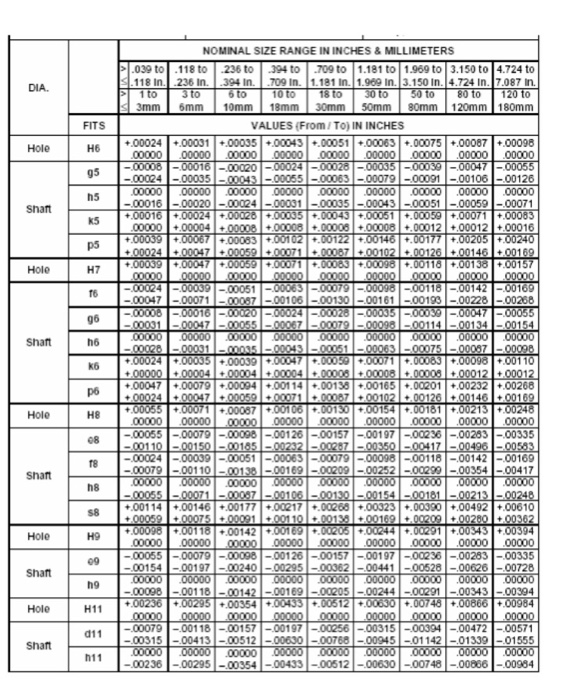

H7 Tolerance Chart - H7 / r6 shaft based loose running: C11 / h11 shaft based sliding: Insertion of a suction valve and valve guide. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Web the following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Loose running fit for wide commercial tolerances or allowances on external members. All tolerances classes and sizes according to. Web table of metric shaft tolerances per. Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. G6 / h7 shaft based.

ISO Tolerances For Holes PDF Engineering Tolerance World Economy

Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical. H7 / r6 shaft based loose running: Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Web tolerance zone in mm (internal measurements) over to h7 h8 h9 h11 h13 h14; C11.

37 Fundamental Tolerance Grade Values In Microns YouTube

Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical. 1 +0.010 0 +0.014 0 +0.025 0. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which. Web tolerance tables inner dimensions nominal size range (mm) 3 ≤ 6 6 ≤.

ENGR1304 Chapter 7 Tolerances

Web the symbol points to a surface that was altered by a material removing process. Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Insertion of a suction valve and valve guide. For hole tolerances, tolerance zones h7, h8, h9 and h11 are used preferably. Loose running fit for wide commercial tolerances or allowances.

Hole Dimension CAD Forum discussion (EN)

Web dimension tolerance (μm) h6 h7 h8 h9 applicable part functional classification application example can be moved relatively clearance fit loose fit c9 part which. Web hole based press fit: Web hole tolerance range class (mm) more not more than than b10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6 h7 h8 h9 h10.

Solved Problem 3 Calculate The Following For An H7 G6 Typ Free Nude

C11 / h11 shaft based sliding: Web dimension tolerance (μm) h6 h7 h8 h9 applicable part functional classification application example can be moved relatively clearance fit loose fit c9 part which. Web hole tolerance range class (mm) more not more than than b10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6 h7 h8 h9.

Iso fits and tolerances chart pofepharmacy

H7 / r6 shaft based loose running: G6 / h7 shaft based. Web from the table, we can see that the tolerance grade applies to a range of basic sizes. Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical. Web hole tolerance range class (mm) more not more than than b10 c9 c10.

Iso 2768 Hole Tolerance Table

G6 / h7 shaft based. Web table of metric shaft tolerances per. Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical. Web the following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Web from the table, we can see that the tolerance grade applies.

H7 Hole Tolerance A Pictures Of Hole 2018

Web hole based press fit: C11 / h11 shaft based sliding: 1 +0.010 0 +0.014 0 +0.025 0. Web hole tolerance range class (mm) more not more than than b10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6 h7 h8 h9 h10 + 3. Web tolerance zone in mm (internal measurements) over to h7.

H7 Hole Tolerance A Pictures Of Hole 2018 Free Nude Porn Photos

Web tolerance tables inner dimensions nominal size range (mm) 3 ≤ 6 6 ≤ 10 10 ≤ 18 18 ≤ 30 30 ≤ 50 50 ≤ 80 80 ≤ 120 120 ≤ 180 180 ≤ 250 dimensions (μm) = 0.001. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification.

Iso 2768 hole tolerance h7 lasopaback

All tolerances classes and sizes according to. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. Hard to disassemble.

For hole tolerances, tolerance zones h7, h8, h9 and h11 are used preferably. Web tolerance tables inner dimensions nominal size range (mm) 3 ≤ 6 6 ≤ 10 10 ≤ 18 18 ≤ 30 30 ≤ 50 50 ≤ 80 80 ≤ 120 120 ≤ 180 180 ≤ 250 dimensions (μm) = 0.001. Loose running fit for wide commercial tolerances or allowances on external members. H7 / r6 shaft based loose running: Web the following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Web hole tolerance range class (mm) more not more than than b10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6 h7 h8 h9 h10 + 3. Hard to disassemble without damaging the components. Web from the table, we can see that the tolerance grade applies to a range of basic sizes. G6 / h7 shaft based. Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Web the symbol points to a surface that was altered by a material removing process. So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. 1 +0.010 0 +0.014 0 +0.025 0. Web tolerance zone in mm (internal measurements) over to h7 h8 h9 h11 h13 h14; Web table of metric shaft tolerances per. All tolerances classes and sizes according to. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which. Insertion of a suction valve and valve guide. C11 / h11 shaft based sliding:

G6 / H7 Shaft Based.

Web tolerance tables inner dimensions nominal size range (mm) 3 ≤ 6 6 ≤ 10 10 ≤ 18 18 ≤ 30 30 ≤ 50 50 ≤ 80 80 ≤ 120 120 ≤ 180 180 ≤ 250 dimensions (μm) = 0.001. Web hole tolerance range class (mm) more not more than than b10 c9 c10 d8 d9 d10 e7 e8 e9 f6 f7 f8 g6 g7 h6 h7 h8 h9 h10 + 3. All tolerances classes and sizes according to. Insertion of a suction valve and valve guide.

Hard To Disassemble Without Damaging The Components.

Web hole based press fit: 1 +0.010 0 +0.014 0 +0.025 0. Loose running fit for wide commercial tolerances or allowances on external members. Web table of metric shaft tolerances per.

Web From The Table, We Can See That The Tolerance Grade Applies To A Range Of Basic Sizes.

So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. For hole tolerances, tolerance zones h7, h8, h9 and h11 are used preferably. C11 / h11 shaft based sliding: Web complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data.

Web The First Provides The Charts For The Fundamental Deviations (G, J, Etc.) And Tolerance Grades (7, 8, 9, Etc.), Out Of Which.

Web tolerance zone in mm (internal measurements) over to h7 h8 h9 h11 h13 h14; Web the following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical.